Exactly How to Select Trusted Sikorsky Parts Distributors for Your Airplane Demands

Exactly How to Select Trusted Sikorsky Parts Distributors for Your Airplane Demands

Blog Article

The Significance of Compatibility and Security Attributes in Sikorsky Parts Choice

In the world of aeronautics, the selection of Sikorsky parts requires a thorough concentrate on compatibility and security functions, as these components are paramount to both operational performance and the securing of human life. Making certain that parts work reduces the probability of mechanical failings, while incorporated safety features contribute considerably to system durability in damaging problems. This conversation emphasizes the urgency of sticking to established regulatory standards and best practices, yet it raises a critical concern: what are the prospective repercussions of disregarding these essential factors to consider in the components option process?

Understanding Compatibility in Aviation Components

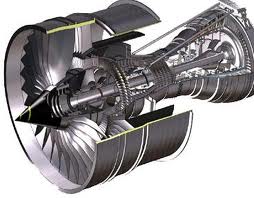

In the world of aeronautics, making certain compatibility amongst elements is vital for operational efficiency and safety. The intricate systems within airplane call for that every component, from engines to avionics, work perfectly together. Compatibility entails not just physical dimensions but additionally product residential or commercial properties, performance requirements, and practical qualities. When selecting Sikorsky components, it is vital to examine whether they satisfy the established criteria and specs for the particular aircraft version.

Appropriate compatibility mitigates the threat of malfunctions and boosts the longevity of the airplane. Engineers need to consider numerous factors, such as load-bearing abilities, environmental problems, and compatibility with existing systems. A rotor blade made for a particular helicopter version should be matched with the proper hub and drive system to guarantee optimum performance.

Failing to make certain compatibility can result in operational disturbances, raised maintenance costs, and security dangers. sikorsky parts distributors. Detailed analysis procedures, consisting of thorough documentation and testing, are crucial in the selection of aviation parts. By prioritizing compatibility, stakeholders can promote a culture of safety and reliability within the aviation sector, inevitably adding to effective goals and the wellness of travelers and team alike

Key Safety Features to Consider

Safety and security features play a vital role in the selection of Sikorsky components, straight affecting the dependability and effectiveness of aircraft procedures. When examining parts, several key safety and security attributes call for attention to ensure optimum efficiency and risk reduction.

Third, performance metrics such as load capacity and fatigue resistance should be evaluated to ensure that components can take care of functional demands without jeopardizing safety. Fourth, the visibility of innovative tracking systems can supply real-time data on part efficiency, permitting positive maintenance and prompt treatments.

Lastly, conformity with aeronautics criteria and policies is non-negotiable. Making certain that components surpass or satisfy industry safety qualifications assurances adherence to finest practices. By concentrating on these essential safety attributes, Sikorsky operators can enhance the safety and security and reliability of their aircraft, inevitably contributing to more secure air travel operations.

Dangers of Incompatible Components

Utilizing inappropriate parts in Sikorsky airplane can cause significant functional risks that endanger both safety and efficiency. The integration of parts that do not meet rigorous compatibility criteria can cause mechanical failures, reduced reliability, and possibly catastrophic crashes (sikorsky parts distributors). Such failures commonly occur from dissimilar specifications, including wrong dimensions, products, or design tolerances that may visit their website not straighten with the aircraft's original layout parameters

Furthermore, the usage of incompatible parts can interrupt critical systems, such as avionics or propulsion, causing a loss of control or diminished maneuverability throughout trip. This not only endangers the team and guests but likewise presents threats to ground spectators and employees. Moreover, the ramifications of utilizing wrong components extend beyond instant safety and security issues; they can additionally bring about costly repair work, prolonged downtime, and boosted responsibility for drivers.

Eventually, making sure that all elements work and abide by the maker's specs is necessary for keeping the stability of Sikorsky aircraft. A positive method to parts selection is vital to minimize these threats, making certain optimum performance and protecting the lives of all those on board.

Regulatory Standards and Conformity

When choosing parts for Sikorsky airplane,Guaranteeing compliance with governing requirements is paramount. Regulative bodies such as the Federal Aviation Management (FAA) and the European Union Air Travel Safety And Security Company (EASA) establish rigid guidelines that control the design, production, and maintenance of aeronautics elements. Adherence to these criteria is vital to ensuring the safety and security and reliability of airplane procedures.

Compliance with governing standards not just safeguards the lives of passengers and team but likewise shields the stability of the airplane itself. Parts should undertake rigorous screening and qualification processes to validate they meet performance and safety and security criteria. This includes examining products, design specs, and making practices.

Moreover, keeping documentation that demonstrates conformity is crucial for accountability and traceability. In the occasion of get more examinations or audits, having comprehensive records makes sure that all parts meet the necessary regulatory demands.

Choosing components that are licensed and certified with established regulatory requirements assists minimize threats associated with non-compliance, such as operational downtimes and legal repercussions. Eventually, prioritizing regulative compliance in parts choice strengthens Sikorsky's commitment to excellence in aviation safety and performance.

Best Practices for Parts Selection

Effective components choice is a critical procedure that directly affects the performance and reliability of Sikorsky airplane. Comprehensive research on each component's specifications, consisting of product properties and compatibility with existing systems, need to be carried out.

Following, prioritize sourcing components from respectable producers that abide by sector standards and have a tried and tested track record of integrity. This step is crucial to maintaining security and ensuring regulative conformity. Additionally, applying a robust verification procedure, including evaluations click for more info and screening, can help verify that picked parts satisfy all functional needs.

Additionally, preserve thorough paperwork of all processes and parts to assist in traceability and accountability. This method not just help in conformity but likewise sustains a lot more reliable maintenance and potential troubleshooting in the future.

Finally, take part in continual training and development for personnel included in parts choice to remain educated concerning the current developments and finest methods in the market (sikorsky parts distributors). By adhering to these ideal techniques, Sikorsky airplane drivers can boost safety and security, dependability, and general performance

Final Thought

In summary, the relevance of compatibility and security attributes in Sikorsky components choice is vital for making certain functional effectiveness and aircraft security. Appropriate compatibility assessment reduces the risks of mechanical failures, while essential safety and security attributes boost system dependability. Adherence to regulative requirements and best practices better safeguards staff and guests, extends aircraft lifespan, and enhances Sikorsky's commitment to air travel excellence. A comprehensive understanding of these variables is important for ideal performance in aeronautics procedures.

Report this page